Component Connection is Crucial for Positional Accuracy & Repeatability

Climax KLDs provide a reliable shaft connection for drive line components of high- speed index packaging machinery, common in the manufacturing of semiconductors.

With the rise of modern technology and the corresponding demand for semiconductors and associated components, efficiency in high-speed index machinery is at an all-time high. As the necessity for these critical components reaches an unprecedented high, increased production is required. This strenuous demand on machinery, especially requirements of positional accuracy and repeatability from drive line components, can cause keyed connections to wear out, become out of sync, and break down. Excessive downtime and loss of productivity are real concerns for maintenance.

(more…)Superior Connection for Vertical Scrubbers Found in Automated Car Wash Systems

Climax Keyless Rigid Moment Couplings provide a superior connection solution for vertical scrubbers, eliminating problems associated with traditional keyed methods.

Cloth-friction wash systems, popular in automated car wash facilities, incorporate the use of soft cloths or brushes. As the vehicle moves through the car wash tunnel, these soft cloths or brushes move around the exterior surface of the vehicle, eliminating unwanted dirt and debris.

This cloth-friction wash system incorporates design features where large vertical mechanisms called scrubbers have multiple cloth strips attached to them. These scrubbers rotate at a very high speed, spinning the cloth strips as they encounter the sides and top of the vehicle while it moves past the scrubbers. The cloths are soft, but since they spin at a high rate of speed, they have a whipping effect on the vehicle as it passes through the wash system.

(more…)Custom Designed Two-Piece Couplings Offer a Superior Solution for Line Shafts

Climax two-piece clamping couplings provide a superior solution for line shaft failed components, saving countless hours of downtime and increasing productivity.

Line shafts are an essential element in the power transmission industry and are used primarily to synchronize multiple components on equipment. Line shafts are common in many industries, including Timber, Forestry, Food Processing, Glass Production, Bottling, and Mills.

Recently, a customer was faced with a challenge where a one-piece tapered bushing used to mount several lever arms onto a line shaft continued to fail. As a result of using a one-piece tapered bushing, maintenance was tasked with the tedious process of removing all other components mounted between the bushing and the egress point. This removal process was often labor-intensive and required extended downtime, resulting in a loss of profits and productivity.

(more…)Large Bore Couplings Provide Solution for Line Shaft Timber Applications

Large Bore Couplings Popular for Sawmills:

Bore Sizes 1-15/16”, 2-7/16”, 2-15/16”, 3-7/16”, 3 15/16”, 4 7/16”

Climax large bore shaft couplings provide a higher strength alternative over antiquated traditional approaches in timbering applications while transmitting higher loads necessary for line shafts.

From initial harvesting to final product, machinery used in forestry (sawmill) applications is constantly subjected to some of the harshest environments and strenuous loads for which an engineer can design.

The true workhorse of the coupling family, rigid couplings can be used in many line shaft applications in the timber industry.

Climax’s state of the art facility, located in Mentor, Ohio, manufactures couplings with up to a 5” bore, with the capability to go larger depending on the application. Climax also offers (more…)

Expanded Metric Offering Provides Necessary Sizes for the Food & Beverage Industries

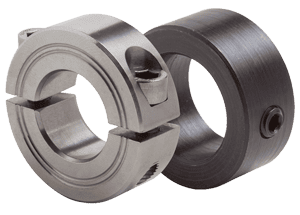

Climax now provides an extended metric size offering in two-piece and set-screw shaft collars styles with bore sizes up to 150mm. This extended offering from stock allows for quick access to larger sizes when needed.

In food processing and bottling applications, processing equipment is subjected to some of the harshest environments possible. Preventative maintenance is a critical step, ensuring that the production line is operating at optimal performance limiting downtime and loss in productivity. Shaft collars provide a vital function and assist in locking or spacing components on a shaft. These silent warriors are often replaced during maintenance cycles to ensure they maintain their holding power.

(more…)Superior Solution for Shaft Connections in Large Bore Applications

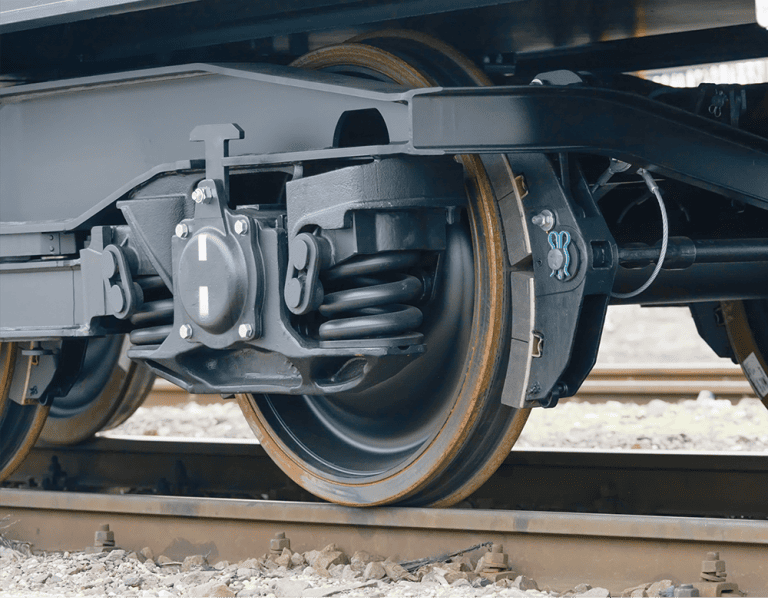

Traditional large cast iron couplings, used to connect shafts in large bore applications found in lumber, steel, rail, recycling, and paper industries, are manufactured from iron and are extremely heavy.

Large cast iron couplings have a bulky design that requires extra room in order to accommodate the oversized outside diameter of the unit. The sheer size of these antiquated couplings puts unnecessary stress on the shaft, and poses risk to damaging the shaft and associated components. In order to attain necessary torque for these applications, cast iron couplings encompass the use of a keyway leading to issues such as wallowing, backlash, fretting corrosion, and fatigue failure, commonly associated with keyways.

Car Wash Tunnel Conveyor Systems Benefit from the use of a Keyless Locking Device

A Keyless Locking Device from Climax provides an alternative to traditional keyed connections in car wash tunnel conveyor applications proving to be cost-effective and maintenance-friendly.

Providing customers a seamless car wash ensures that they leave the facility happy and with a clean car. Although the requirement for equipment maintenance may seem daunting and costly, proper maintenance of a car wash is extremely important in providing a positive experience. Many car wash facilities incorporate the use of an underground tunnel conveying system that moves the vehicle through the washing process. Typically this type of car wash system can reach upwards of a half-million dollars in equipment.

(more…)316 Stainless Steel Corrosion Resistant Shaft Collars

Climax 316 stainless steel shaft collars provide a locking solution that eliminates the likelihood of contamination from corrosion in environments where frequent wash-downs are common and downtime is costly.

Climax offers a solution to the corrosive environments persistent in many applications in the Food and Beverage Industry. Shaft collars manufactured from 316SS are extremely corrosion resistant making them ideal for applications in harsh environments. Since stainless steel is easy to sanitize, in inert to corrosion, and is proven durable, it is considered the industry standard for food processing, packaging, breweries, bottling, and canning applications.

Download our Corrosion Resistant Shaft Collars Brochure (PDF) or see our complete offering by product type below:

CR1C-Series One-Piece Clamping Collars

CR2C-Series Two-Piece Clamping Collars

Eliminating Problems Associated with Corrosion Contamination in the Beer & Ale Industry

Climax 316 stainless steel shaft collars provide for a locking solution that eliminates the likelihood of contamination from corrosion in an environment where frequent wash-downs are common and downtime is costly.

At the end of 2017 there were approximately 8,000 breweries in the United States according to America’s Beer Distributors website (nbwa.org). The estimated current market value of the beer industry is $114 billion dollars. As consumers continue to demand this popular beverage, breweries will need to maintain and replace equipment in order to keep up with production. Corrosion in breweries continues to prove challenging to this industry. Choosing the wrong metals can have an impact on flavor, can cause contamination in the product, and consequent downtime.

KLD Mechanical Interference Fit an Optimal Solution for Sawmill Systems & Planar/Feed Tables

Climax Keyless Locking Devices withstand the constant pounding associated with timber processing applications making them an ideal replacement for expensive and time consuming traditional interference fit connections.

Sawmill Systems and Planer/Feed Tables commonly incorporate traditional keyed connections when attaching feed rollers in sawmill equipment. Using a keyed connection adds weight and cost not only to the shaft but to every component on the shaft. Over time, keyways cause fretting corrosion, allowing for backlash, and do not transmit bending moments or axial loads.

Sawmill Systems and Planer/Feed Tables commonly incorporate traditional keyed connections when attaching feed rollers in sawmill equipment. Using a keyed connection adds weight and cost not only to the shaft but to every component on the shaft. Over time, keyways cause fretting corrosion, allowing for backlash, and do not transmit bending moments or axial loads.

Climax Keyless Locking Assemblies can be used in place of a keyed connection removing these disadvantages especially when subjected to extreme environments where constant load reverses are common. Keyless locking devices use multiple screws with opposing tapers creating a 360° contact mechanical interference fit. Where pin retention is used in sawmill equipment, using a C133 or C405 locking assembly eliminates the need for (more…)